More Complex Products Can Be Formed

Higher injection pressure and acceleration performance.

Casting of Magnesium Alloy Components as easy as Plastic Injection Molding

The Thixomolding process uses magnesium alloy chips as raw material. By transporting and cutting the chips with the returning screw and simultaneously heating them by the barrel, the chips eventually become a semi-solid sludge that remains at the screw front end. When enough sludge has accumulated at the screw front end, the screw is pushed forward and the semi-solid sludge is injected into the closed mold cavity and takes shape. Thixomolding's mold and forming material are similar to casting processes, while the injection processes are close to plastic injection forming.

Higher injection pressure and acceleration performance.

The measurement, speed, pressure, temperature, etc., could all be controlled in the molding process precisely.

The magnesium alloy slurry is in a completely closed environment, the temperature of the semi-solid slurry is lower, and less melting magnesium alloy in the barrel.

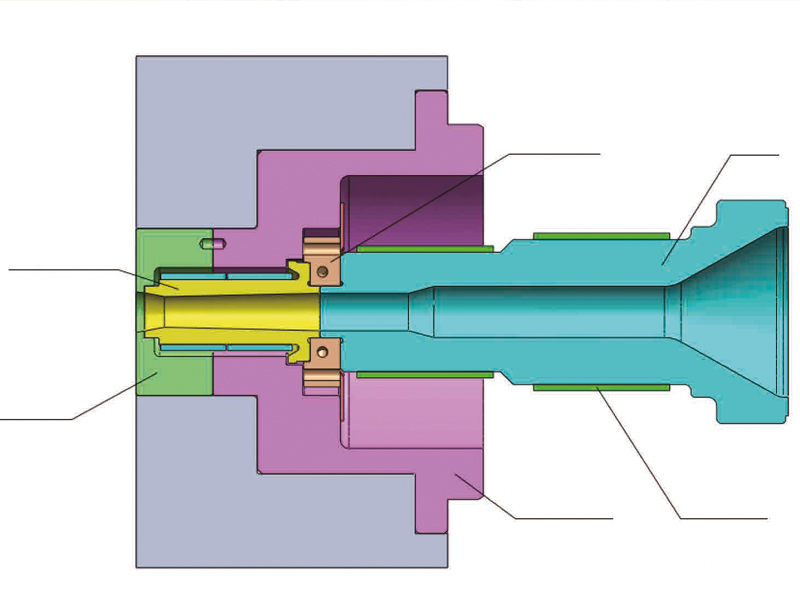

The hot runner technology keeps the magnesium alloy material in the runner of the mold within a semi-solid state by heating. The hot runner system is an extension of the nozzle that eliminates the need to remove the barrel from the hot runner after shutdown and only needs to be heated to bring the hot runner to the desired temperature for the next injection. This technology is especially suitable for mass production in general, also of components with high raw material cost as well as high product quality requirements.

The Thixomolding machine produces high-precision parts with high injection pressure and acceleration performance, which enables the creation of more complex products. In the molding process, factors such as temperature, speed, pressure, and temperature can be precisely controlled.