High Precision

With more power and faster response, the A5 series gives you a wider processing range. Your recurring investment costs will be reduced.

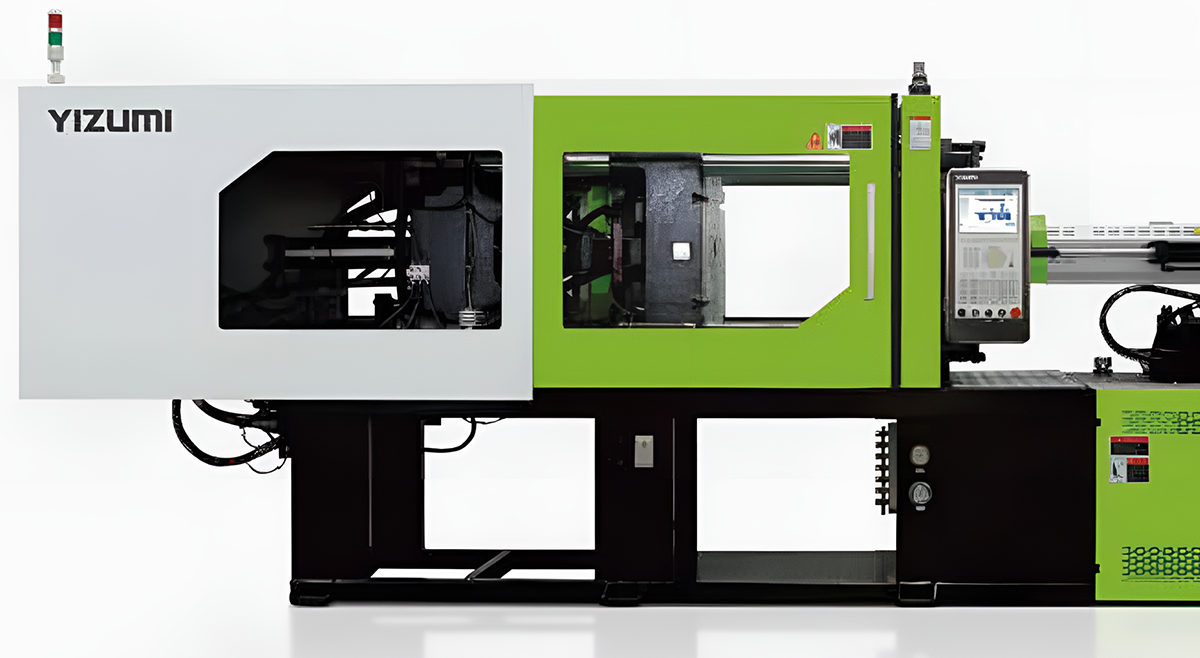

Yizumi A5 Series High-end Servo System Plastic Injection Molding Machine is a standard high-end servo plastic injection molding machine newly created by IPD model. It offers wider processing range and lower recurring investment costs with larger features and faster response. Optimized injection units ensure precision and stability. Uniform tension molding technology ensures durability and reliability. Available with clamping forces from 600 to 5,600 kN.

With more power and faster response, the A5 series gives you a wider processing range. Your recurring investment costs will be reduced.

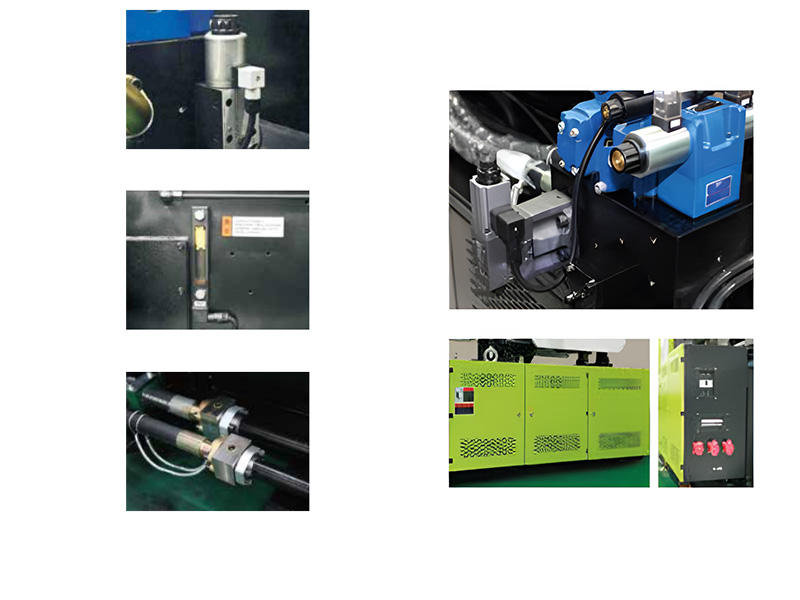

Fully optimize injection unit to ensure precision and stability.

The third-generation servo system. Low noise, strong power and quick response in operation.

The third-generation servo system has been improved and optimized in the internal structure of motor, the standard of magnetic steel, the selection of oil pump and the development of drive software to achieve superior performance in stability reliability, durability, energy conservation, efficiency and low noise; the servo system uses 30%-80% less energy than conventional hydraulic machines. The accuracy of closed-loop hydraulic oil temperature control, which is the new function, is ±0.5℃ with further increased stability.

A5 series of medium-large machines (above 650T) have identified the core customer value, which is reliable and stable. In this context, YIZUMI IPD-program team follows this trend and focuses its research on the reliability, stability and plasticizing performance of medium-large injection molding machine, which fully meets the needs of customers.