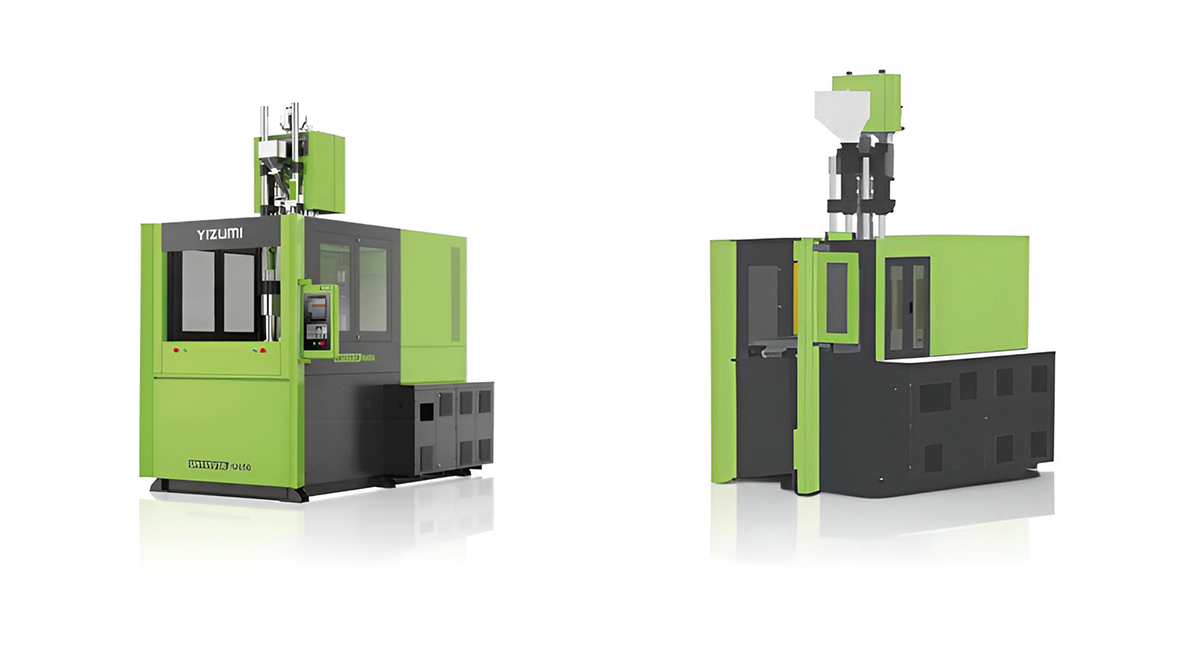

Thanks to its third generation servo system, it offers superior performance in terms of stability, reliability, durability, energy saving and efficiency. VM series machines use 30%-80% less energy than conventional hydraulic machines thanks to the servo system. Check the brochure for more detailed technical information.