More Stable

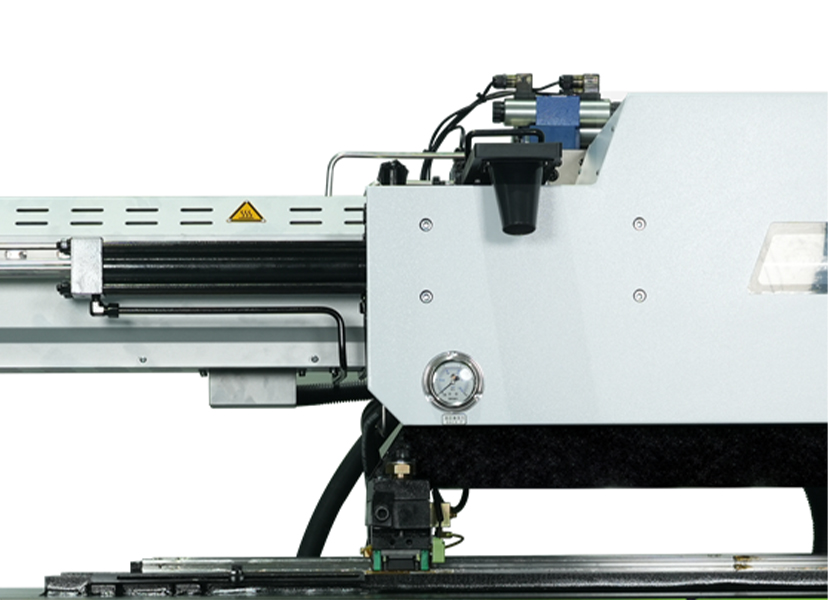

New linear guide design reduces product defects. Upgraded to the new KEBA series controller with larger screens and smoother page switching.

Boasting enhanced efficiency and consistent energy savings, the SKIII series also excels in stability and user experience. Its design incorporates the interchangeability of the SK/A5 platform, thanks to continual optimization. Distinguished as the top choice among small to medium-sized injection molding machines, the SKIII series underscores a commitment to elevating the user journey. Available with clamping forces from 900 to 10,000 kN.

New linear guide design reduces product defects. Upgraded to the new KEBA series controller with larger screens and smoother page switching.

With a newly upgraded power system, the injection speed is increased by 15%-25%, while the average injection speed for machines below 530T exceeds lüümm/s, significantly improving production efficiency and product quality.

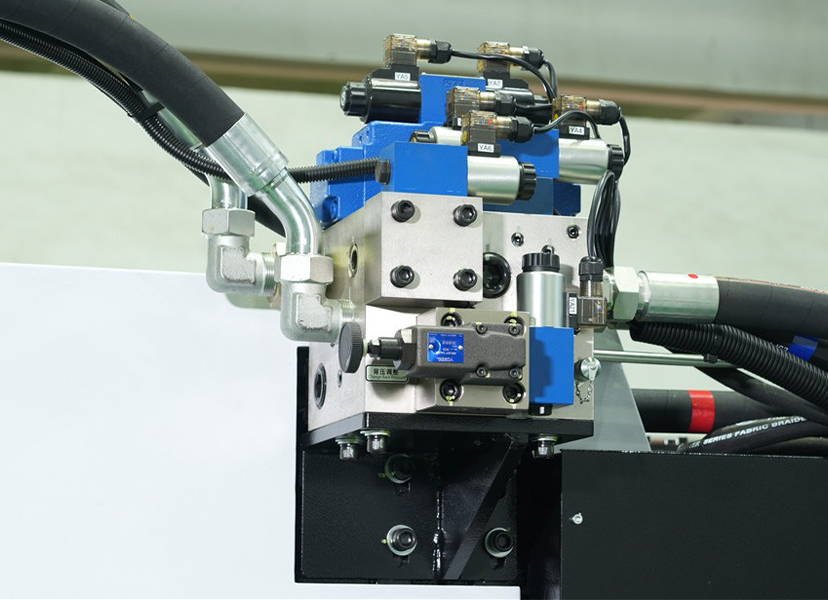

Adopt a new generation servo system with gear pump for higher rotation speed and lower energy consumption.

The all-new servo drive system adopts one-piece air duct technology, offering high speed and low noise; Optimized oil circuit design for lower pressure loss and more energy-saving: Use optimized hydraulic principle and valve plate pipeline design to reduce oil pressure loss and improve energy-saving.

Boasting enhanced efficiency and consistent energy savings, the SKIII series also excels in stability and user experience. Its design incorporates the interchangeability of the SK/A5 platform, thanks to continual optimization.