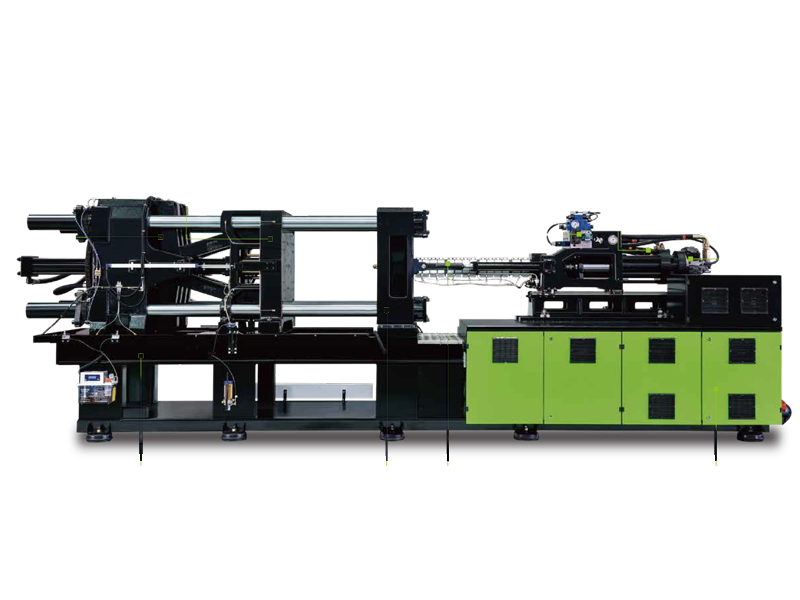

Communication of Product Concept

Customers provide the concept of product requirements. The professionals from YIZUMI will assist customers in the design and development of the product to improve customers' production efficiency and product competitiveness.