Smart and Efficient

The A6 Series offers high productivity and superior product quality while optimizing production processes with AI-powered features.

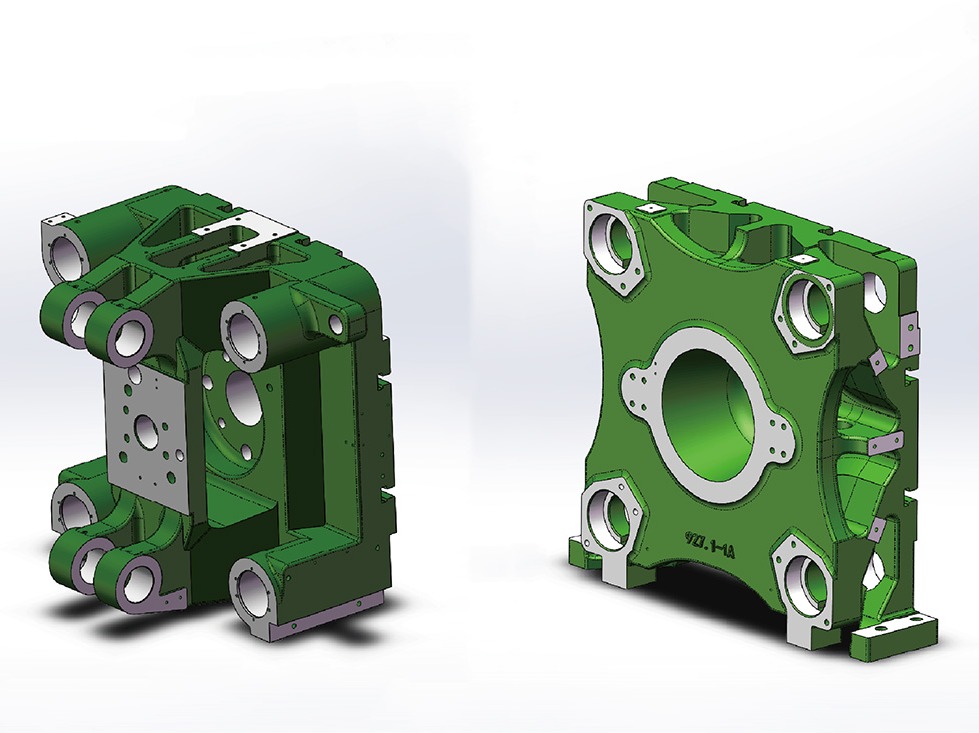

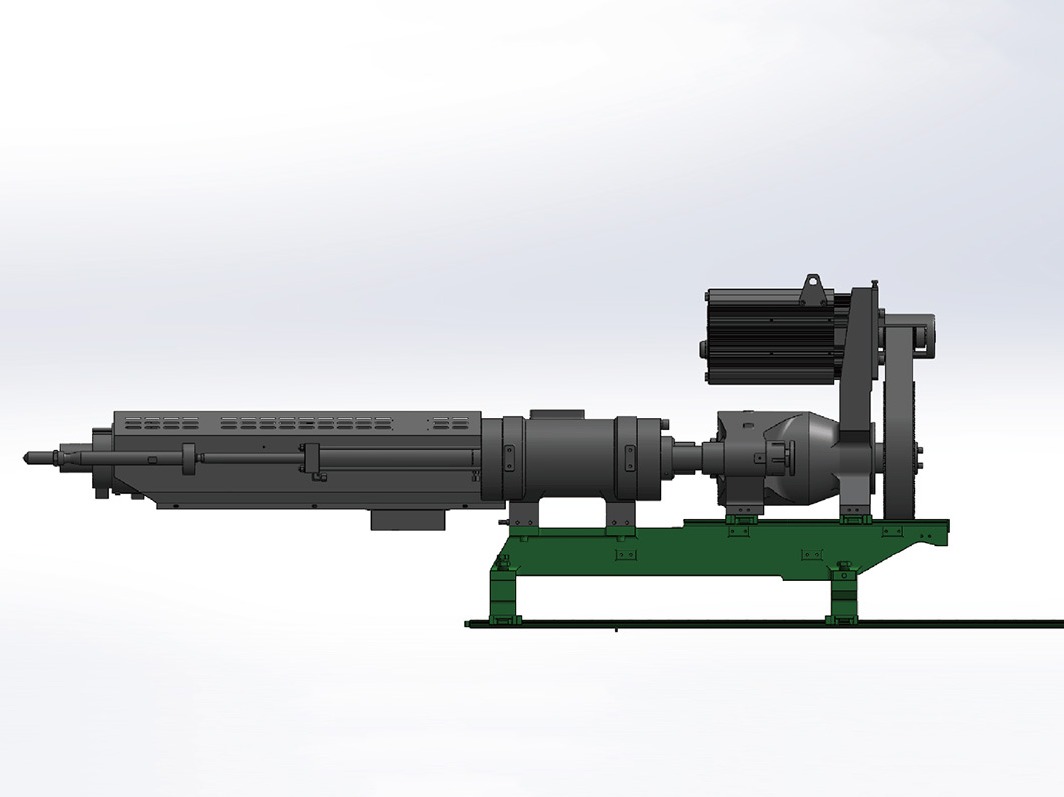

Next Generation YIZUMI A6 Series Plastic Injection Molding Machine makes your production processes more efficient and intelligent with the power of artificial intelligence. Built with YIZUMI's “IPD 2.0” process, the A6 Series offers precision molding, energy efficiency and smart technology. It provides high productivity with clamping forces ranging from 900-18,500 kN. Equipped with the KEBA Control Unit, this series offers an optimized production experience with innovative features such as Smart Clamping Force Management and Energy Consumption Management. The Smart Mold Opening feature ensures precise positioning, while the Smart Clamping system performs proactive force monitoring and maintenance to prevent errors. While extending machine life with real-time preventive maintenance, advanced technologies such as electric material handling and intelligent weight control ensure energy savings and excellent product accuracy. It's time to take your production quality to the next level with the A6 Series!

The A6 Series offers high productivity and superior product quality while optimizing production processes with AI-powered features.

The energy-saving electric picking system reduces production costs by operating with higher precision.

YIZUMI's intelligent clamping force management system determines the optimum clamping force, ensuring stable product quality and easy handling.

Built with YIZUMI's "IPD 2.0" process, the A6 Series offers precision moulding, energy efficiency and smart technology. It provides high productivity with clamping forces ranging from 900-18,500 kN. Equipped with the KEBA Control Unit, this series offers an optimised production experience with innovative features such as Intelligent Clamping Force Management and Energy Consumption Management.